Designed in Canada. built for serious brewers.

What Causes a Fermenter to Heat Up?

December 29, 2023 10 min read

What Causes a Fermenter to Heat Up?

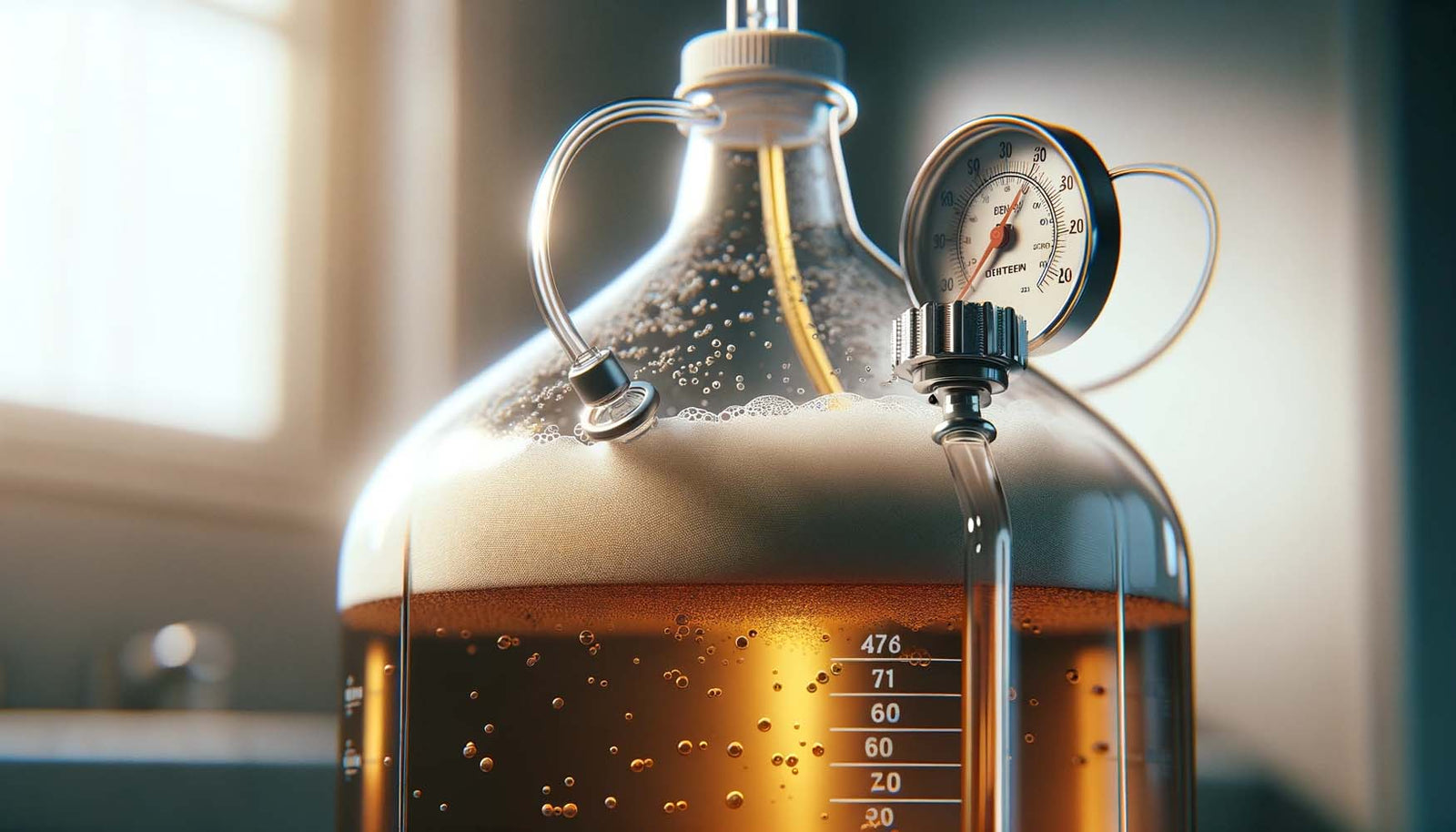

Fermentation is a fascinating process that converts sugars into alcohol, producing the flavors and aromas we associate with beer, wine, and other fermented beverages. However, it's not uncommon for fermenters to heat up during this intricate procedure, which can have both positive and negative effects on the end product. Understanding the factors that contribute to fermenter heat is essential for brewers and winemakers alike.

Understanding the Basics of Fermentation

Before delving into the causes of fermenter heat, it's important to grasp the fundamentals of fermentation itself. Fermentation is a fascinating biological process that has been used by humans for centuries to produce various food and drink products. It is carried out by microorganisms, primarily yeast, which consume sugar molecules and release alcohol and carbon dioxide as byproducts. This process occurs at specific temperature ranges, which can significantly impact the final product's flavor and aroma.

The Role of Microorganisms in Fermentation

Microorganisms, particularly yeast strains, play a vital role in fermentation. These tiny organisms have the incredible ability to convert simple sugars into alcohol and carbon dioxide through a process known as anaerobic respiration. Different yeast strains have unique characteristics that can affect the fermentation process and the resulting flavors. Some yeast strains are known for producing fruity esters, while others are prized for their ability to create complex flavors and aromas. They are truly the unsung heroes of the fermentation world.

But how exactly do these microorganisms produce heat during fermentation? The answer lies in the science of microbial metabolism. As yeast consumes sugar molecules, it breaks them down using enzymes, releasing energy in the form of heat. This heat is intrinsic to the fermentation process and is a natural byproduct of the yeast's metabolic activity.

The Science Behind Fermentation Heat

The phenomenon of fermentation heat is rooted in the intricate workings of microbial metabolism. When yeast cells come into contact with sugar molecules, they activate specific enzymes that break down the sugars into smaller compounds. This process not only releases energy in the form of heat but also produces alcohol and carbon dioxide as byproducts.

The intensity of heat production during fermentation can vary depending on several factors. One crucial factor is the yeast strain used. Different yeast strains have different metabolic rates, which can influence the amount of heat generated. Additionally, the sugar content of the fermentation mixture also plays a role. Higher sugar concentrations can lead to more vigorous fermentation, resulting in increased heat production.

Another factor that affects fermentation heat is the volume of the fermentation. Larger fermentation volumes tend to generate more heat due to the increased metabolic activity of the yeast cells. This is why it's essential to have proper temperature regulation in place during fermentation to prevent overheating, which can negatively impact the final product.

Understanding the science behind fermentation heat is crucial for anyone involved in the fermentation process. By carefully controlling the temperature and other variables, fermenters can ensure that the yeast cells work their magic and produce the desired flavors and aromas in the final product. So the next time you enjoy a glass of wine or a slice of freshly baked bread, take a moment to appreciate the fascinating world of fermentation and the heat it generates.

Factors Contributing to Fermenter Heat

In addition to the inherent heat generated during fermentation, several factors can contribute to the increased temperature of a fermenter. Understanding these factors is crucial for brewers and winemakers to maintain control over the fermentation process.

When it comes to the temperature of a fermenter, yeast strains play a significant role. Different yeast strains exhibit varying levels of fermentation vigor, which directly affects the amount of heat produced. Some yeast strains are known to be more robust and can generate more heat during fermentation compared to others. Brewers and winemakers must carefully select yeast strains based on their desired temperature range and heat tolerance to avoid any overheating issues that may arise.

Another factor that can influence the temperature in a fermenter is the sugar content of the fermentation mixture. The amount of sugar present in the mixture can affect the metabolic activity of the yeast. Fermentations with higher sugar content tend to produce more heat as the yeast break down the excess sugars. It is essential for brewers and winemakers to monitor and adjust the sugar content to regulate the temperature during fermentation effectively.

Aside from yeast strains and sugar content, the volume of the fermentation also plays a role in the heat generated. Smaller fermentations tend to heat up more quickly compared to larger ones. This is due to the higher concentration of yeast cells and sugar molecules in a smaller volume, leading to a more rapid fermentation process and increased heat production. Brewers and winemakers should consider the vessel size and adjust fermentation parameters accordingly to manage the temperature effectively.

Controlling the temperature during fermentation is crucial for the quality and consistency of the final product. Too high of a temperature can result in off-flavors, stressed yeast, and even stalled fermentations. On the other hand, maintaining the ideal temperature range for the specific yeast strain and fermentation process can enhance the flavors and aromas of the finished beer or wine.

In conclusion, understanding the factors that contribute to fermenter heat is essential for brewers and winemakers. By carefully selecting yeast strains, monitoring and adjusting sugar content, and considering the fermentation volume, they can maintain optimal temperature conditions and achieve the desired outcomes in their fermentation process.

The Consequences of Overheating in Fermentation

While some heat during fermentation is expected and even beneficial, excessive heat can lead to undesirable consequences in the final product. Brewers and winemakers must be aware of the potential risks associated with overheating during fermentation.

Impact on Yeast Viability

Yeast viability is greatly affected by high temperatures. Excessive heat can stress the yeast cells, leading to decreased viability and impaired fermentation. This can result in incomplete sugar conversion, off-flavors, and a lack of desirable aroma compounds. Maintaining proper fermentation temperature is crucial to ensure yeast health and a successful fermentation.

When yeast cells are exposed to temperatures above their optimal range, they struggle to perform their metabolic functions efficiently. The heat causes the yeast cells to become more active, consuming nutrients and producing waste products at a faster rate. This increased metabolic activity can lead to the depletion of essential nutrients, such as vitamins and minerals, which are necessary for healthy yeast growth.

In addition to nutrient depletion, high temperatures can also disrupt the delicate balance of the yeast's internal environment. The heat can denature enzymes and proteins within the yeast cells, rendering them ineffective in carrying out their biological functions. This can result in a decreased ability to convert sugars into alcohol and carbon dioxide, leading to a sluggish fermentation process.

Furthermore, excessive heat can cause the yeast cells to undergo oxidative stress. The increased temperature accelerates the production of reactive oxygen species, which can damage the yeast's DNA, proteins, and lipids. This oxidative stress can further impair the yeast's ability to carry out fermentation, resulting in a lower yield of alcohol and a higher likelihood of off-flavors.

Effect on Flavor Profile

Overheating during fermentation can significantly alter the flavor profile of the final product. High temperatures can promote the production of undesirable off-flavors, such as fusel alcohols, which can contribute to harsh, solvent-like tastes in the beverage. Additionally, excessive heat can cause volatile aromas to evaporate, leading to a loss of desirable aromatic compounds. Careful temperature control is necessary to achieve the desired flavor profile.

Fusel alcohols, also known as higher alcohols, are produced by yeast during fermentation. They are typically present in small amounts and contribute to the complexity and character of the beverage. However, when the fermentation temperature exceeds the optimal range, the production of fusel alcohols can increase significantly. These compounds have a higher boiling point than ethanol, the desired alcohol in fermented beverages, and can therefore remain in the final product. The presence of excessive fusel alcohols can result in a harsh and unpleasant taste, reminiscent of nail polish remover or rubbing alcohol.

In addition to the negative impact on flavor, overheating can also lead to the loss of delicate aromatic compounds. Many desirable flavors and aromas in fermented beverages are volatile and can easily evaporate at high temperatures. This can result in a less aromatic and less flavorful final product. The loss of these compounds can be particularly detrimental in beverages where the aroma plays a significant role, such as wines and certain styles of beer.

Furthermore, overheating can cause chemical reactions that alter the composition of the beverage. For example, the Maillard reaction, which is responsible for the browning of food and the development of rich flavors, can occur at high temperatures. While the Maillard reaction can contribute to desirable flavors in certain foods, it can also lead to the formation of undesirable compounds in fermented beverages. These compounds can impart off-flavors and decrease the overall quality of the product.

Overall, maintaining proper temperature control during fermentation is essential for producing high-quality beverages. By avoiding excessive heat, brewers and winemakers can ensure yeast viability, prevent the production of off-flavors, and preserve the delicate flavors and aromas that contribute to a superior drinking experience.

Controlling the Temperature of Your Fermenter

Given the potential drawbacks of overheating during fermentation, implementing effective temperature control measures is paramount for brewers and winemakers. Proper temperature regulation ensures consistent fermentation and desirable flavor development.

When it comes to brewing and winemaking, temperature plays a crucial role in the success of the fermentation process. Yeast, the microorganism responsible for converting sugars into alcohol, is highly sensitive to temperature. If the temperature is too high, the yeast can become stressed and produce off-flavors. On the other hand, if the temperature is too low, the fermentation can slow down or even stop completely.

Importance of Temperature Regulation

Maintaining the appropriate fermentation temperature is essential for yeast health, fermentation efficiency, and flavor development. Temperature control allows for better control over fermentation kinetics, ensuring the production of desirable flavors while minimizing the risk of off-flavors caused by high temperatures.

Yeast health is crucial for a successful fermentation. By keeping the temperature within the optimal range, yeast cells remain active and healthy, leading to a more efficient fermentation process. This means that the yeast can consume sugars more effectively, resulting in higher alcohol content and better flavor extraction from the ingredients.

Furthermore, temperature regulation also affects the production of esters and other flavor compounds. Different yeast strains produce different flavors at different temperatures. By carefully controlling the temperature, brewers and winemakers can manipulate the flavor profile of their final product. For example, a lower fermentation temperature may result in a cleaner and more crisp flavor, while a higher temperature can lead to more fruity and complex flavors.

Techniques for Maintaining Optimal Temperature

Various techniques can be employed to regulate the temperature of your fermenter. Water baths, cooling jackets, and temperature-controlled chambers are popular options. These methods involve surrounding the fermenter with a temperature-regulated environment to keep the temperature stable throughout the fermentation process.

Water baths are a simple and cost-effective way to control the temperature. By placing the fermenter in a larger container filled with water, the heat can be absorbed or released to maintain the desired temperature. Cooling jackets, on the other hand, are typically made of insulated material and can be wrapped around the fermenter. They are equipped with cooling elements that can be connected to a refrigeration system to lower the temperature when needed.

For more advanced temperature control, temperature-controlled chambers are often used. These chambers are specifically designed to maintain a constant temperature throughout the fermentation process. They are equipped with heating and cooling systems that can be adjusted to the desired temperature range.

Additionally, using temperature-controlling equipment, such as heating pads or cooling systems, can help maintain a consistent temperature throughout the fermentation process. These devices are often attached directly to the fermenter and can be programmed to maintain a specific temperature range.

Regular temperature monitoring and adjustments are important to avoid any temperature fluctuations that could negatively impact the fermentation. By using a thermometer or a temperature controller, brewers and winemakers can keep a close eye on the temperature and make necessary adjustments to ensure a successful fermentation.

Overall, controlling the temperature of your fermenter is crucial for achieving the desired flavor profile and ensuring a successful fermentation. By implementing effective temperature control measures, brewers and winemakers can have better control over the fermentation process and produce high-quality beverages.

Troubleshooting Common Fermentation Heat Problems

Despite careful temperature regulation, brewers and winemakers may encounter issues related to fermenter heat. Recognizing and addressing these problems promptly is crucial for maintaining the quality of the final product.

Identifying Overheating Issues

Monitoring the temperature of the fermenter closely is essential to detect overheating issues. If the temperature consistently rises above the optimal range for your fermentation, it indicates a problem. Unusual off-flavors, sluggish fermentation, or apparent stress in yeast cells can also be signs of overheating.

Solutions for Overheating Problems

If overheating occurs during fermentation, there are several steps that can be taken to mitigate the issue. Utilizing cooling methods such as water baths or cooling jackets can help bring the temperature down. Adjusting the fermentation parameters, such as reducing the sugar content or using a different yeast strain with lower heat generation, may also be necessary. Prompt action is crucial to prevent further detrimental effects on yeast performance and flavor development.

In Conclusion

Understanding the causes of fermenter heat is vital for brewers and winemakers who strive to create high-quality fermented beverages. By considering factors like yeast strain selection, sugar content, fermentation volume, and temperature control techniques, producers can maintain optimal temperature conditions during fermentation. Careful temperature regulation not only ensures a successful fermentation process and yeast viability but also plays a critical role in shaping the flavors and aromas of the final product.

Now that you're equipped with the knowledge of what causes a fermenter to heat up and the importance of temperature control in the brewing process, it's time to take your brewing to the next level with Bräu Supply. Our innovative Unibräu systems, including the all-in-one Unibräu Pro, are designed with the highest quality 304 stainless steel and electric power at their core, ensuring precise temperature regulation and optimal fermentation conditions. With the world's fastest brew system, the Unibräu Pro, you can complete a day's brew in under 4 hours, while our HERMS system offers a traditional, efficient brewing experience. Don't forget to explore our Unitank jacketed conical fermenters, capable of 15psi pressure and designed for ease of use with standard tri-clamp openings. With Bräu Supply, you'll find the perfect brewing setup tailored to your needs, complete with an extensive range of accessories. Check out our products and start crafting exceptional brews with confidence and quality equipment.

More Articles on Fermentation

https://brausupply.ca/blogs/news/mastering-the-cold-side-of-brewing-a-comprehensive-guide

https://brausupply.com/blogs/news/what-causes-a-fermenter-to-heat-up

https://brausupply.com/blogs/news/what-is-the-basic-function-of-the-fermenter

Subscribe

Sign up to get the latest on sales, new releases and more …