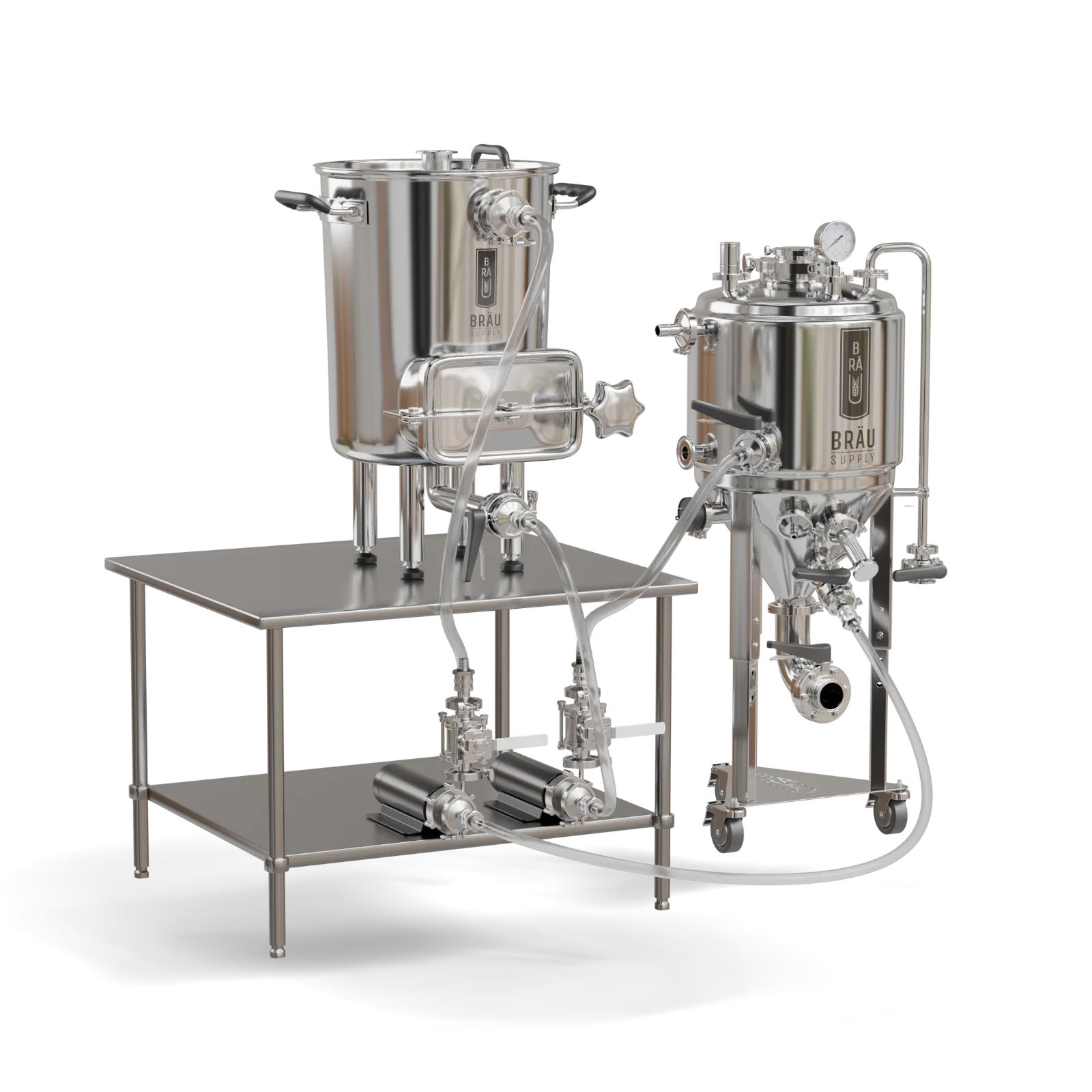

BRÄUPRO 5G 240V – ALL-IN-ONE ELECTRIC BREWING SYSTEM WITH 8 GAL UNITANK

All-in-One Electric Brewing System with 8 Gal Jacketed Unitank (240V)

Brew, chill, and ferment in a single 30 L (8 gal) Unitank—without transfers, chemicals, or unnecessary complexity.

The BräuPro 5G (240V) is a fully integrated electric brewing system that combines a precision-built DrainPro™ bottom-drain mash tun with a jacketed conical Unitank fermenter. Designed for advanced homebrewers seeking higher heat performance and faster brew days, it delivers a complete mash-to-fermentation workflow in a compact two-vessel configuration powered by a 240V electric system.

Boil directly in the fermenter for heat-based sanitation. Chill through the built-in jacket using cool tap water or glycol. Ferment under pressure and transfer closed. Each stage is engineered to reduce oxygen exposure, simplify cleaning, and improve consistency at small scale.

Ideal for brewers producing 3 to 6 gallons (12–23 L) of finished beer with professional-level heat performance and control.

System Overview

The BräuPro 5G replaces traditional multi-vessel homebrew setups with a streamlined two-vessel architecture that still delivers full capability: mash, lauter, boil, chill, and ferment—without open transfers or chemical sanitation.

The DrainPro™ bottom-drain mash tun improves runoff consistency and simplifies cleaning through true bottom drainage. Boiling directly in the jacketed fermenter reduces exposure points while ensuring sanitary conditions before knockout.

Integrated temperature control, tri-clamp connectivity throughout, and pressure-capable fermentation bring commercial-style workflow to a refined small-scale system with faster heat-up and stronger boil performance.

Why BräuPro

Two Vessels. Complete Workflow.

Mash in a dedicated tun, then boil and ferment in a single jacketed vessel for a simplified and highly controlled process.

Bottom-Drain Mash Architecture

The DrainPro™ design provides true bottom drainage for improved lauter performance, reduced dead space, and easier post-brew cleanup compared to traditional side-drain kettles.

Reduced Transfers, Reduced Risk

Eliminating wort transfers between boil and fermentation significantly lowers oxidation potential and contamination risk.

Chemical-Free Sanitation

Boiling in the fermenter sanitizes the vessel by heat alone—no chemical sanitizers required.

High-Performance Electric Heating

The 240V configuration delivers faster heat-up times and stronger boil intensity compared to 120V systems, improving brew-day efficiency while maintaining precise control.

Accurate Temperature Control

The SV2 Electric Brewery Controller provides stable mash control and consistent boil performance for repeatable results.

Closed-Loop Jacketed Chilling

The jacketed Unitank supports chilling with either tap water or glycol through a sealed cooling loop—eliminating immersion chillers and exposed coils.

Pressure Fermentation Ready

Rated for pressure fermentation and closed transfers using standard tri-clamp hardware.

Cooling & Temperature Control Architecture

The BräuPro 5G includes integrated jacketed fermentation cooling as standard. The Unitank jacket supports either tap-water circulation or dedicated glycol cooling through a sealed loop—allowing you to configure the system based on your environment and brewing goals.

Water Fermentation Cooling (Included)

The base system includes a Fermenter Temperature Control Kit and Water Connection Kit. Tap water is circulated through the jacket using quick-disconnect fittings for stable fermentation temperature control in moderate environments.

- Closed-loop jacket circulation

- Quick-disconnect fittings and hose set included

- Integrated controller-based pump activation

Upgrade to Glycol Fermentation Cooling

For tighter temperature control in warmer environments, the BräuPro 5G can be configured with a dedicated glycol chiller. Glycol systems provide improved temperature stability and enhanced crash cooling performance.

- Dedicated glycol chiller with tri-clamp coolant connections

- 3/8" insulated glycol line set with tri-clamp adapters

- Independent pump control via the temperature controller

Professional Cooling Configuration (Glycol + Counterflow)

While the jacket is designed for fermentation temperature control and crash cooling, rapid knockdown from boiling is best achieved using a dedicated heat exchanger. The Professional Cooling Configuration pairs the glycol system with the Coil-in-Coil Counterflow Chiller for efficient knockout prior to fermentation.

- Rapid knockout from boiling to pitch temperature

- Reduced load on glycol compressor

- Shorter brew day and improved system efficiency

- Dedicated 1/2" knockout line set included

Glycol systems are optimized for fermentation temperature management. For high-efficiency knockout performance, the counterflow configuration is recommended.

Brewing & Fermentation Workflow Considerations

The BräuPro 5G is designed around a single-vessel boil and fermentation workflow. This configuration prioritizes sanitation, simplicity, and repeatability, but fermentation time must be considered when planning brew frequency.

If you plan to brew again before fermentation is complete, additional fermenting capacity will be required. This applies to any brewing setup where fermentation duration exceeds brew intervals.

Many BräuPro users expand their setup with additional fermenters, allowing brewing to continue while fermentation proceeds separately.

A Modular Growth Path

- Brew without waiting for fermentation to finish

- Scale fermenting capacity independently

- Maintain closed, sanitary transfers

- Add equipment incrementally as needs evolve

This modular approach mirrors professional brewery design, where brewhouse utilization and fermentation capacity are planned independently.

What’s Included — BräuPro 5G (240V)

The BräuPro 5G ships as a complete brewing and fermentation system designed for 240V operation. Add ingredients, a hydrometer, and a pH meter to begin brewing.

Fermenter & Core Components

-

30 L (8 gal) jacketed conical Unitank fermenter

- Vessel rated to 15 psi

- Jacket rated to 5 psi

- Drop-in ruler with volume markings

- Stainless steel fermenter blow-off assembly

- Sample valve

- Analog pressure gauge (0–30 psi)

- 15 psi pressure reducing valve

Tri-Clamp Hardware

- 2" tri-clamp elbow

- 2" butterfly valve

- 2" tri-clamp and gasket

- 1" ball valve

- 1.5" butterfly valve × 4

- 6"–3" tri-clamp cap

- 6" tri-clamp clamp and gasket

- 3" cap, clamp, and gasket

- 1.5" tri-clamp and gasket × 17

- 1.5" cap × 2

Brewing System

- 5500 W ULWD tri-clamp brewing element (240V configuration)

- SV2 Electric Brewery Controller

- Brew pump with quick-disconnect adapters

- DrainPro™ 10 gal (40 L) bottom-drain mash tun with lid

- Note: The 10G DrainPro mash tun features a simplified bottom-drain design and does not include a grain door. Images shown reflect larger capacities.

- Mash tun false bottom

- Vorlauf double clamp arm

Tubing & Connectivity

- 1.5" tri-clamp to quick-disconnect adapters × 6

- Quick-disconnect female to 5/8" barb adapters × 6

- 4 m (13 ft) high-temperature silicone tubing

Control & Transfer Kits

Technical Specifications

Dimensions

Fermenter (30 L / 8 gal)

- Diameter: 35 cm (13.75")

- Height: 85 cm (33.5")

- Height to top port: 100 cm (39.4")

Mash Tun (40 L / 10 gal)

- Diameter: 35 cm (13.8")

- Height: 40.5 cm (16")

Brewing Capacity

- Brew volume range: 3 gal (12 L) to 6 gal (23 L)