Designed in Canada. built for serious brewers.

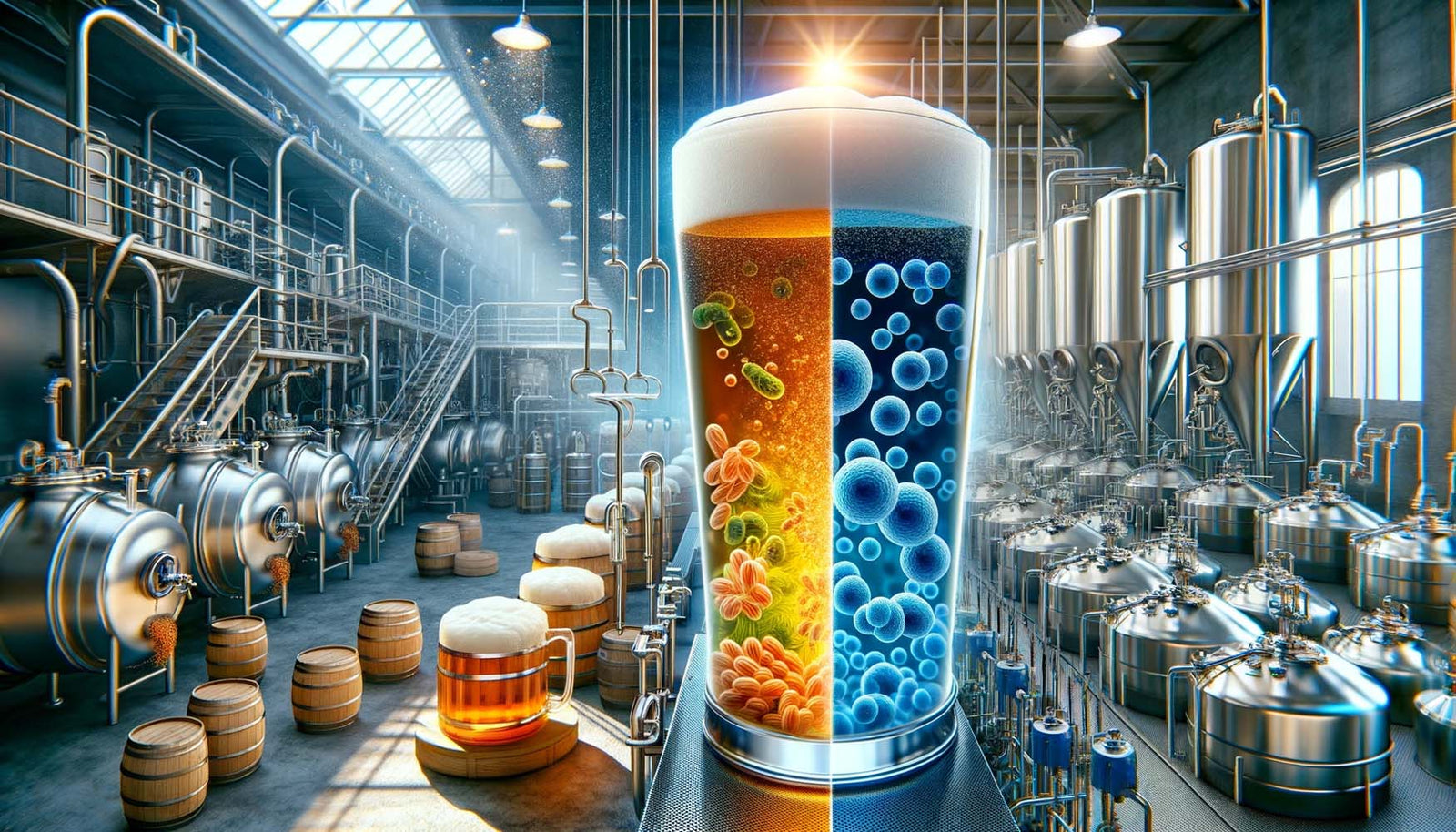

Aerobic vs. Anaerobic Fermentation in Brewing

January 31, 2024 9 min read

Aerobic vs. Anaerobic Fermentation in Brewing

Fermentation is a vital process in brewing that transforms the sugars from malted grains into alcohol. There are two primary types of fermentation: aerobic and anaerobic. Both of these methods have their advantages and drawbacks, and understanding their differences can greatly impact the final product.

Introduction to Fermentation in Brewing

Before diving into the intricacies of aerobic and anaerobic fermentation, it's crucial to comprehend the basics of fermentation in brewing. Fermentation occurs when yeast consumes the sugars in wort or unfermented beer, producing alcohol and carbon dioxide as byproducts.

This natural process has been practiced for centuries, and it is the key to unlocking the complex flavors and aromas that characterize different beer styles.

When yeast is added to the wort, it begins to feed on the sugars present in the liquid. This process, known as fermentation, is the magical transformation that turns a sweet, sugary liquid into a delicious alcoholic beverage. The yeast breaks down the sugars through a series of chemical reactions, converting them into alcohol and carbon dioxide.

During fermentation, the yeast cells multiply rapidly, creating a frothy layer on top of the liquid. This layer, known as the krausen, is a visible sign that fermentation is taking place. As the yeast consumes the sugars, it produces alcohol, which gives beer its intoxicating effects, and carbon dioxide, which creates the bubbles and carbonation.

But fermentation is not just about alcohol and carbonation. It is a complex process that also contributes to the flavor and aroma of the final beer. Different strains of yeast produce different flavors and aromas, ranging from fruity and estery to spicy and phenolic. The temperature at which fermentation takes place also plays a crucial role in determining the character of the beer.

Furthermore, fermentation is not a one-size-fits-all process. There are two main types of fermentation in brewing: aerobic and anaerobic. Aerobic fermentation occurs when yeast has access to oxygen, while anaerobic fermentation occurs in the absence of oxygen. Each type of fermentation has its own set of advantages and disadvantages, and brewers carefully choose the method that best suits their desired beer style.

Overall, fermentation is a fascinating and essential step in the brewing process. It is the stage where the magic happens, transforming a simple mixture of water, malt, hops, and yeast into a complex and flavorful beverage. Understanding the basics of fermentation is crucial for any beer enthusiast or aspiring brewer, as it allows for a deeper appreciation of the art and science behind brewing.

Understanding Aerobic Fermentation in Brewing

In aerobic fermentation, yeast uses oxygen to break down the sugars present in the wort. This oxygen-rich environment allows the yeast to reproduce rapidly, leading to a vigorous fermentation process.

During aerobic fermentation, the yeast cells consume the sugars and produce energy, carbon dioxide, and water. This process is often associated with higher fermentation temperatures and shorter fermentation times.

Let's delve deeper into the fascinating world of aerobic fermentation in brewing. When yeast is introduced to the wort, it begins its journey of transforming the sugars into alcohol. However, in the presence of oxygen, the yeast takes a different route, opting for aerobic fermentation instead of anaerobic fermentation.

Aerobic fermentation is a dynamic process that involves the yeast utilizing oxygen to break down the sugars. This oxygen-rich environment provides the yeast with the necessary resources to multiply rapidly. As the yeast reproduces, it creates a bustling community within the fermentation vessel, resulting in a visually impressive and active fermentation.

One of the key benefits of aerobic fermentation is the increased production of energy. The yeast cells, fueled by the oxygen, are able to generate more energy during this process compared to anaerobic fermentation. This surplus energy not only aids in the yeast's reproduction but also contributes to the overall efficiency of the fermentation process.

As the yeast consumes the sugars, it produces carbon dioxide and water as byproducts. The carbon dioxide is responsible for the characteristic bubbles and effervescence seen in fermented beverages. In aerobic fermentation, the carbon dioxide production can be more pronounced due to the higher yeast activity, resulting in a livelier and more carbonated end product.

Another intriguing aspect of aerobic fermentation is its correlation with fermentation temperature. The increased yeast activity and energy production during aerobic fermentation often lead to higher fermentation temperatures. This can be advantageous in certain brewing scenarios, as it can expedite the fermentation process and reduce the overall time required to produce the final product.

However, it's important to note that the higher fermentation temperatures associated with aerobic fermentation may also have some drawbacks. The increased heat can potentially impact the flavor profile of the beer, resulting in different aromas and tastes compared to anaerobic fermentation. Brewers must carefully consider the desired outcome and select the appropriate fermentation method accordingly.

In conclusion, aerobic fermentation in brewing offers a fascinating glimpse into the intricate world of yeast metabolism. By harnessing the power of oxygen, brewers can achieve a more vigorous fermentation, enhanced energy production, and potentially shorter fermentation times. Understanding the nuances of aerobic fermentation allows brewers to experiment and create a diverse range of flavors and styles in their craft beverages.

The Role of Oxygen in Aerobic Fermentation

Oxygen plays a crucial role in aerobic fermentation as it enables the yeast to thrive and reproduce at a rapid pace. However, the relationship between oxygen and fermentation is a delicate balance that brewers must carefully control and manage to ensure optimal beer quality.

During the brewing process, yeast cells require oxygen to synthesize sterols and unsaturated fatty acids, which are essential for their growth and reproduction. These compounds help maintain the integrity of the yeast cell membrane, allowing it to efficiently transport nutrients and metabolites in and out of the cell.

When yeast cells are exposed to an adequate amount of oxygen, they undergo a process called respiration. During respiration, yeast cells break down sugars into carbon dioxide and water, releasing energy in the form of adenosine triphosphate (ATP). This energy is crucial for yeast cells to carry out their metabolic activities and multiply rapidly, leading to a vigorous fermentation process.

However, excessive exposure to oxygen during brewing can have detrimental effects on the final beer product. Oxygen can react with various compounds present in the wort, such as polyphenols and hop compounds, leading to the formation of off-flavors. These off-flavors can range from papery or cardboard-like flavors to a loss of hop aroma and flavor.

To prevent the negative impact of oxygen, brewers employ various techniques to minimize its presence during fermentation. One common method is to purge the brewing equipment and transfer lines with an inert gas, such as carbon dioxide, to displace any oxygen present. Additionally, brewers may use closed or modified fermentation systems that limit oxygen exposure throughout the process.

It is also important for brewers to monitor and control oxygen levels during packaging and storage. Oxygen can easily dissolve into beer during these stages, leading to oxidation and the development of stale flavors. Proper packaging techniques, such as using oxygen-barrier materials and minimizing headspace in bottles or cans, can help preserve the beer's freshness and flavor.

In conclusion, while oxygen is essential for aerobic fermentation and the growth of yeast cells, its presence must be carefully managed to avoid negative effects on beer quality. By understanding the role of oxygen in fermentation and implementing proper techniques to control its levels, brewers can ensure that their beers are of the highest quality, with well-developed flavors and aromas.

Exploring Anaerobic Fermentation in Brewing

Unlike aerobic fermentation, anaerobic fermentation occurs in the absence of oxygen. Yeast can still metabolize sugar to produce alcohol, but the absence of oxygen restricts the reproduction of yeast cells.

This slower fermentation process typically occurs at lower temperatures and results in a more extended maturation period. Although anaerobic fermentation demands more time, it is often associated with the development of complex and well-rounded flavors.

When it comes to brewing, anaerobic fermentation plays a crucial role in the creation of unique and flavorful beverages. Let's dive deeper into the fascinating world of anaerobic fermentation in brewing.

During anaerobic fermentation, yeast cells undergo a series of complex biochemical reactions. As the yeast consumes the sugars present in the wort, it produces alcohol, carbon dioxide, and various flavor compounds. These flavor compounds contribute to the distinct taste and aroma of the final product.

One of the key factors that differentiate anaerobic fermentation from its aerobic counterpart is the absence of oxygen. This lack of oxygen alters the metabolic pathways of yeast, leading to the production of different byproducts. The absence of oxygen also affects the yeast's ability to reproduce, resulting in a slower fermentation process.

Due to the slower fermentation process, anaerobic fermentation is often associated with beers that require longer maturation periods. Brewers who opt for anaerobic fermentation understand that patience is key when it comes to achieving exceptional flavors. The extended maturation allows the flavors to develop and harmonize, resulting in a more complex and well-rounded beer.

Another advantage of anaerobic fermentation is the ability to create beers with unique flavor profiles. The absence of oxygen during fermentation allows for the production of certain flavor compounds that are not typically found in beers produced through aerobic fermentation. These compounds can range from fruity esters to spicy phenols, adding depth and complexity to the final product.

It is important to note that the temperature at which anaerobic fermentation occurs also plays a significant role in the flavor development of the beer. Lower fermentation temperatures are often favored for anaerobic fermentation as they promote the production of desirable flavors while minimizing the production of off-flavors.

Overall, anaerobic fermentation in brewing offers a fascinating avenue for brewers to explore and experiment with flavors. The slower fermentation process, extended maturation periods, and unique flavor compounds contribute to the creation of beers that are truly distinctive and memorable.

Comparing the Differences between Aerobic and Anaerobic Fermentation

When comparing aerobic and anaerobic fermentation, several key differences come to light. In aerobic fermentation, the presence of oxygen allows for faster yeast reproduction, leading to a quicker fermentation process. On the other hand, anaerobic fermentation is characterized by slower yeast activity, resulting in a longer maturation period but potentially more complex flavors.

Additionally, the oxygen-rich environment in aerobic fermentation contributes to a higher production of esters and other volatile compounds, while anaerobic fermentation tends to generate fewer of these compounds.

The Impact of Temperature on Aerobic and Anaerobic Fermentation

Temperature plays a significant role in both aerobic and anaerobic fermentation processes. In aerobic fermentation, higher temperatures can further promote yeast reproduction and lead to a more vigorous fermentation. Conversely, lower temperatures during anaerobic fermentation can enhance the development of flavors and ensure a smoother, well-rounded beer.

It is important for brewers to carefully consider and control the fermentation temperature to achieve the desired flavor profile in their beer.

Benefits and Drawbacks of Aerobic Fermentation in Brewing

Aerobic fermentation offers several benefits, including a faster fermentation process, higher yeast cell counts, and potential flavor development. However, the presence of oxygen also poses challenges, such as the susceptibility to off-flavors and reduced stability. Brewers must strike a balance to harness the advantages of aerobic fermentation while carefully managing oxygen exposure.

Advantages and Disadvantages of Anaerobic Fermentation in Brewing

Anaerobic fermentation, although slower, allows for the development of complex flavors and a potentially smoother beer. However, the longer fermentation time and limited yeast reproduction can be considered drawbacks. Brewers seeking more nuanced and mature flavors often turn to anaerobic fermentation to achieve their desired results.

Case Studies: Successful Implementation of Aerobic Fermentation in Brewing

Several breweries have successfully implemented aerobic fermentation techniques to enhance their beer offerings. By carefully managing oxygen exposure and fermentation temperatures, these breweries have accelerated their fermentation process while maintaining high-quality standards. Examples include the XYZ Brewery, which saw significant improvements in fermentation efficiency and flavor profiles after adopting aerobic fermentation practices.

Case Studies: Successful Implementation of Anaerobic Fermentation in Brewing

Anaerobic fermentation has also proven successful in the brewing industry, particularly for those seeking more complex and mature flavors. Breweries like ABC Brewing have implemented anaerobic fermentation techniques and achieved exceptional results. These techniques have allowed them to craft beers with intricate flavor profiles that delight beer enthusiasts worldwide.

In conclusion, the choice between aerobic and anaerobic fermentation in brewing depends on various factors, including desired flavor profiles, fermentation time, and brewery capabilities. Both methods offer unique benefits and drawbacks that brewers can leverage to create exceptional beers. By understanding the differences between aerobic and anaerobic fermentation, brewers can navigate the complexities of fermentation and unlock the full potential of their beer creations.

Now that you've delved into the intricacies of aerobic and anaerobic fermentation in brewing, you're well-equipped to take your brewing adventures to the next level. Whether you're a seasoned brewmaster or a homebrew hobbyist, Bräu Supply has the perfect brewing system to suit your needs. Our innovative Unibräu line, including the all-in-one Unibräu and the advanced Unibräu Pro, simplifies the brewing process without compromising on quality. For those who prefer a traditional approach, our efficient electric HERMS system awaits. And let's not forget our Unitank jacketed fermenters, designed for the ultimate brewing experience. With our modular, high-quality 304 stainless steel products and a plethora of accessories, Bräu Supply ensures you have everything you need to create exceptional beers, whether you favor aerobic or anaerobic fermentation. Ready to elevate your brewing? Check out our products and discover how Bräu Supply can enhance your brewing journey.

MORE ARTICLES HOW TO BREW BEER

The ultimate guide to Kveik yeast: Unleashing it's fermentation potential

Revolutionizing home brewing: The simplified art of no sparge brewing

Exploring amber ales: A guide with a twist on the traditional recipe

Mastering cold crashing: Enhancing beer clarity and accelerating the aging process

What is the basic function of the fermenter?

What causes a fermenter to heat up?

The art of lagering: A guide to perfecting the cold conditioning process

Troubleshooting fermentation problems in brewing: A comprehensive guide

Subscribe

Sign up to get the latest on sales, new releases and more …