Designed in Canada. built for serious brewers.

Diacetyl Rest: Understanding Its Importance

January 30, 2024 10 min read

Diacetyl Rest: Understanding Its Importance

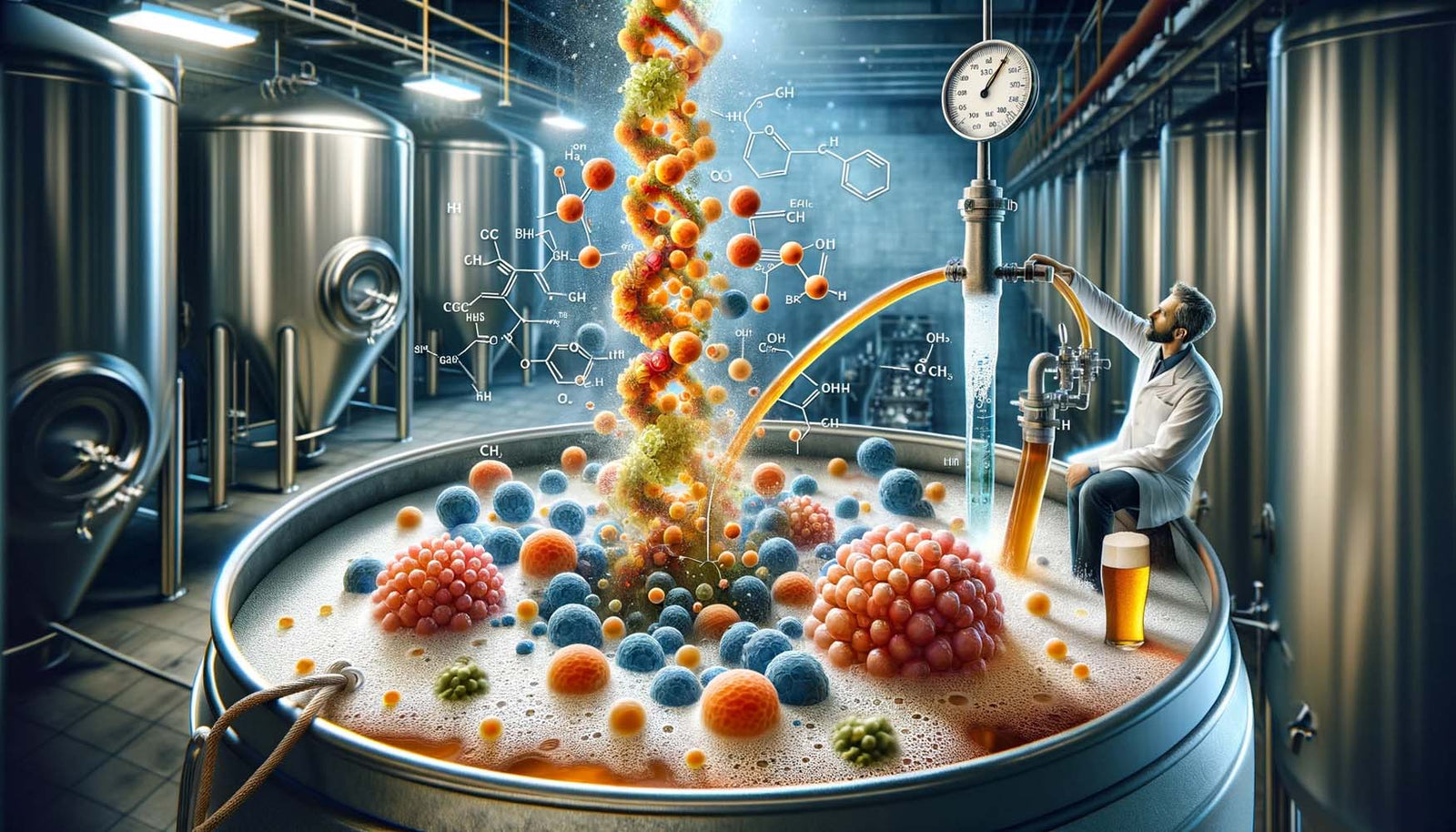

In the world of beer brewing, there are many factors that contribute to the final flavor, aroma, and overall quality of the end product. One such factor that is often misunderstood or overlooked is the diacetyl rest. In this article, we will explore the importance of diacetyl rest in beer brewing and how it can enhance the flavor profile of your brew.

What is Diacetyl Rest?

Before we dive into the importance of diacetyl rest, let's first understand what it actually is. Diacetyl is a natural byproduct of the fermentation process. It is a volatile compound that is produced by yeast during the early stages of fermentation. Diacetyl has a distinct buttery or butterscotch-like flavor and aroma.

During diacetyl rest, the beer is allowed to sit at a slightly elevated temperature after the primary fermentation has finished. This resting period allows the yeast to clean up and re-absorb any remaining diacetyl, resulting in a smoother and cleaner final product.

The Science Behind Diacetyl Rest

To understand why diacetyl rest is important, we need to delve into the science behind it. Diacetyl is produced by yeast during fermentation as a byproduct of the conversion of alpha acetolactate, a precursor compound, into diacetyl. This conversion is catalyzed by an enzyme called alpha acetolactate decarboxylase.

During the early stages of fermentation, the yeast is actively producing and releasing diacetyl into the beer. However, as the fermentation progresses, the yeast starts to reabsorb and break down the diacetyl through the action of another enzyme called diacetyl reductase. This reabsorption process is slow at lower temperatures but significantly accelerated at higher temperatures.

When the beer is subjected to diacetyl rest, the slightly elevated temperature provides an optimal environment for the yeast to continue working and reduce diacetyl levels. The increased temperature speeds up the reabsorption process, allowing the yeast to efficiently break down the diacetyl and convert it into other compounds that contribute to the beer's flavor and aroma.

Furthermore, diacetyl rest also promotes the production of diacetyl reductase, the enzyme responsible for breaking down diacetyl. The increased temperature stimulates the yeast to produce more diacetyl reductase, enhancing the efficiency of diacetyl reduction.

The Role of Diacetyl in Brewing

While diacetyl is considered an off-flavor in most beer styles, it plays a crucial role in the development of certain beer styles, such as lagers. In some beer styles, a certain level of diacetyl is desired to contribute to the overall flavor profile. However, excessive diacetyl can overpower other flavors and lead to an unpleasant taste.

Therefore, it is important for brewers to strike a delicate balance and carefully control the levels of diacetyl in their beer. This is where diacetyl rest comes into play, as it provides an opportunity for the yeast to continue working and reduce diacetyl levels to an acceptable range.

By allowing the beer to undergo diacetyl rest, brewers can ensure that any excess diacetyl is eliminated, resulting in a beer with a cleaner and more balanced flavor profile. This process is particularly important for lagers, where a crisp and clean taste is highly desired.

It is worth noting that the duration of diacetyl rest can vary depending on the specific beer style and fermentation conditions. Typically, it lasts for a few days to a week, allowing sufficient time for the yeast to complete the reabsorption and breakdown of diacetyl.

In conclusion, diacetyl rest is a crucial step in the brewing process that allows brewers to control and reduce the levels of diacetyl in their beer. By providing an optimal environment for yeast activity and enzyme production, diacetyl rest ensures a final product that is free from off-flavors and exhibits the desired characteristics of the chosen beer style.

The Importance of Diacetyl Rest in Beer Brewing

Now that we have a solid understanding of what diacetyl rest is, let's explore its importance in beer brewing and how it contributes to the overall quality of the final product.

Enhancing Beer Flavor with Diacetyl Rest

Diacetyl rest is a key step in the brewing process that allows the yeast to remove any diacetyl present in the beer. This removal helps to enhance the overall flavor of the beer by reducing the buttery or butterscotch-like notes that can be attributed to high diacetyl levels.

During the fermentation process, yeast produces various compounds, including diacetyl. While small amounts of diacetyl can contribute to the complexity of certain beer styles, excessive levels can be detrimental to the flavor profile. Diacetyl rest provides an opportunity for the yeast to metabolize and reabsorb diacetyl, resulting in a cleaner and more balanced flavor.

By giving the yeast time to clean up and reabsorb diacetyl, brewers can achieve a cleaner and more balanced flavor profile in their beer. This is especially important in beer styles that require a crisp and clean finish, such as lagers.

Preventing Off-Flavors through Diacetyl Rest

Another important aspect of diacetyl rest is its ability to prevent the formation of off-flavors in beer. When diacetyl levels are too high, it can result in an unpleasant taste that resembles artificial butter or even popcorn. This can significantly impact the overall enjoyment of the beer.

During fermentation, yeast produces diacetyl as a natural byproduct. In some cases, the yeast is able to consume and convert diacetyl into other compounds, but this process takes time. If the beer is not given sufficient time for diacetyl rest, the diacetyl levels may remain high, leading to off-flavors.

By implementing diacetyl rest, brewers can mitigate the risk of off-flavors and ensure that their beer is free from any unwanted taste. This is particularly crucial for professional brewers who strive for consistency and excellence in their products.

Additionally, diacetyl rest is especially important in certain beer styles, such as Czech Pilsners and Oktoberfest lagers, where a clean and crisp flavor profile is highly desired. These beer styles rely on the absence of diacetyl to achieve their characteristic taste.

Furthermore, diacetyl rest also plays a role in the aging process of beer. Allowing the yeast to clean up diacetyl during this rest period can contribute to the overall stability and longevity of the beer, ensuring that it maintains its quality over time.

In conclusion, diacetyl rest is a crucial step in the brewing process that enhances beer flavor and prevents off-flavors. By giving the yeast time to metabolize and reabsorb diacetyl, brewers can achieve a cleaner and more balanced flavor profile. Whether it's for achieving a crisp finish in lagers or maintaining consistency in professional brewing, diacetyl rest is an essential technique for producing high-quality beer.

The Process of Diacetyl Rest

Now that we understand why diacetyl rest is important let's delve into the process itself and explore the factors that can affect its effectiveness.

Diacetyl rest is a crucial step in the brewing process that helps to ensure a clean and crisp final product. It involves a period of elevated temperature and extended fermentation time to reduce the presence of diacetyl, a compound that can give beer an undesirable buttery or butterscotch flavor.

Timing and Temperature in Diacetyl Rest

The timing and temperature during diacetyl rest are critical factors that can influence its effectiveness. The general rule of thumb is to perform diacetyl rest once the primary fermentation has reached its anticipated final gravity. This is typically around 75-80% attenuation.

Timing is key because performing diacetyl rest too early can interrupt the active fermentation process and lead to incomplete attenuation. On the other hand, delaying diacetyl rest for too long can result in the yeast becoming less active and less capable of reducing diacetyl effectively.

As for the temperature, diacetyl rest is commonly performed at a slightly elevated temperature, typically around 65-70 degrees Fahrenheit. This temperature range helps to activate the enzymes responsible for diacetyl reduction and accelerate the reabsorption process.

During this period, the yeast continues to metabolize and convert diacetyl into less flavorful compounds, resulting in a cleaner and more enjoyable beer.

Monitoring Diacetyl Levels during Rest

Monitoring diacetyl levels during the rest period is crucial to ensure that the desired reduction is achieved. This can be done by taking samples of the beer and analyzing them for diacetyl levels using sensory evaluation or laboratory analysis.

By regularly sampling the beer and assessing its diacetyl levels, brewers can make informed decisions about the duration of the rest period. It's important to note that the duration of diacetyl rest may vary depending on various factors such as yeast strain, beer style, and fermentation conditions. Some brewers perform diacetyl rest for a few days, while others may extend it up to a week or more.

Additionally, other flavor compounds and off-flavors can also be monitored during this time to ensure the overall quality of the beer. This comprehensive approach helps brewers fine-tune their processes and achieve consistent results.

In conclusion, diacetyl rest is a critical step in the brewing process that requires careful timing, temperature control, and monitoring. By following these guidelines, brewers can ensure that their beer is free from unwanted diacetyl flavors, resulting in a more enjoyable drinking experience for beer enthusiasts.

Common Misconceptions about Diacetyl Rest

Now that we have covered the importance and process of diacetyl rest, let's address some common misconceptions and myths surrounding this brewing technique.

One common myth is that all beer styles require diacetyl rest. While diacetyl rest is crucial in certain beer styles, such as lagers, it may not be necessary or beneficial in others. Some beer styles, such as ales, naturally have lower levels of diacetyl, and excessive rest can lead to unnecessary flavor changes.

It is important for brewers to understand the specific requirements of each beer style and make informed decisions about whether or not diacetyl rest is necessary. For example, ales that are fermented at higher temperatures may not produce significant amounts of diacetyl, eliminating the need for a rest period.

Another misconception is that diacetyl rest can fix or mask other off-flavors in beer. While diacetyl rest can help reduce diacetyl levels and improve overall flavor, it cannot fix other underlying issues in the beer. It's important for brewers to address any off-flavors through proper brewing techniques and ingredient selection.

Off-flavors can be caused by a variety of factors, such as improper fermentation temperature, contamination, or poor ingredient quality. Diacetyl rest should not be relied upon as a cure-all for these issues. Instead, brewers should focus on identifying and addressing the root causes of off-flavors to ensure the best possible beer quality.

Understanding the Risks and Benefits

Like any brewing technique, diacetyl rest comes with its own set of risks and benefits. When done correctly, diacetyl rest can result in a cleaner and more flavorful beer. However, if not properly executed, it can lead to unintended flavor changes or even contamination.

One risk associated with diacetyl rest is the potential for introducing oxygen into the beer. Oxygen exposure can lead to oxidation, which can cause off-flavors and shorten the shelf life of the beer. Brewers must take precautions to minimize oxygen exposure during the rest period, such as using airtight fermentation vessels and carefully transferring the beer without splashing.

On the other hand, the benefits of diacetyl rest can be significant. By allowing the yeast to continue working at a slightly elevated temperature, diacetyl rest can help ensure complete fermentation and reduce the levels of diacetyl in the beer. This can result in a cleaner and more balanced flavor profile, enhancing the overall drinking experience.

Brewers should carefully consider the specific beer style and fermentation conditions before deciding on the necessity and duration of diacetyl rest. Consulting with experienced brewers or conducting small-scale experiments can help mitigate any potential risks and ensure the best possible outcome.

Ultimately, the decision to perform diacetyl rest should be based on a thorough understanding of the beer style, the fermentation process, and the desired flavor profile. By dispelling common misconceptions and taking the necessary precautions, brewers can harness the benefits of diacetyl rest and produce exceptional beers that delight the palate.

Tips for a Successful Diacetyl Rest

Now that we have covered the importance, process, and misconceptions of diacetyl rest, let's conclude with some practical tips to help you achieve a successful diacetyl rest in your brewing endeavors.

Best Practices for Diacetyl Rest

First and foremost, it is essential to plan ahead and determine the appropriate timing for diacetyl rest based on the beer style you are brewing. This will help you optimize the fermentation process and achieve the desired flavor profile.

Additionally, maintaining a stable temperature during diacetyl rest is crucial. Fluctuations in temperature can disrupt the yeast's activity and slow down the diacetyl reduction process. Utilizing a reliable temperature control system or a dedicated fermentation chamber can help you achieve more consistent results.

Troubleshooting Common Diacetyl Rest Issues

If you encounter any issues during diacetyl rest, such as incomplete diacetyl reduction or unexpected flavor changes, don't despair. Remember that brewing is both an art and a science, and it often takes practice and experimentation to achieve the desired results.

Consider adjusting the duration of diacetyl rest, fine-tuning the temperature, or even experimenting with different yeast strains to find the optimal conditions for your specific brewing setup. Keeping detailed brewing notes and seeking advice from experienced brewers can also provide valuable insights.

In conclusion, diacetyl rest is an essential step in beer brewing that helps improve the flavor profile and overall quality of the final product. By understanding the science behind diacetyl, implementing proper diacetyl rest techniques, and debunking common misconceptions, brewers can achieve exceptional results and create beers that are both delicious and consistent.

So, the next time you embark on a brewing adventure, don't forget to give diacetyl rest the attention it deserves. Your taste buds will thank you!

Ready to take your brewing to the next level and ensure your diacetyl rest is as effective as possible? Look no further than Bräu Supply, the pioneers of the all-in-one brew system, the Unibräu. Our high-quality 304 stainless steel systems, from the space-saving Unibräu Pro to the efficient HERMS setup, are designed with the home brewer in mind. With electric power at the core and the most available accessories in the business, our modular products provide unparalleled value and quality. Whether you're interested in our innovative Unibräu countertop system, the professional-grade Unibräu Pro, or our traditional HERMS system with its unique laser cut mash tun false bottom, we've got you covered. Plus, our Unitank jacketed fermenters are top-of-the-line, pressure-capable, and designed for ease of use. Don't miss out on the opportunity to enhance your brewing process with Bräu Supply's exceptional range of products. Check out our products today and brew with confidence!

MORE ARTICLES HOW TO BREW BEER

The ultimate guide to Kveik yeast: Unleashing it's fermentation potential

Revolutionizing home brewing: The simplified art of no sparge brewing

Exploring amber ales: A guide with a twist on the traditional recipe

Mastering cold crashing: Enhancing beer clarity and accelerating the aging process

What is the basic function of the fermenter?

What causes a fermenter to heat up?

The art of lagering: A guide to perfecting the cold conditioning process

Troubleshooting fermentation problems in brewing: A comprehensive guide

Subscribe

Sign up to get the latest on sales, new releases and more …