Designed in Canada. built for serious brewers.

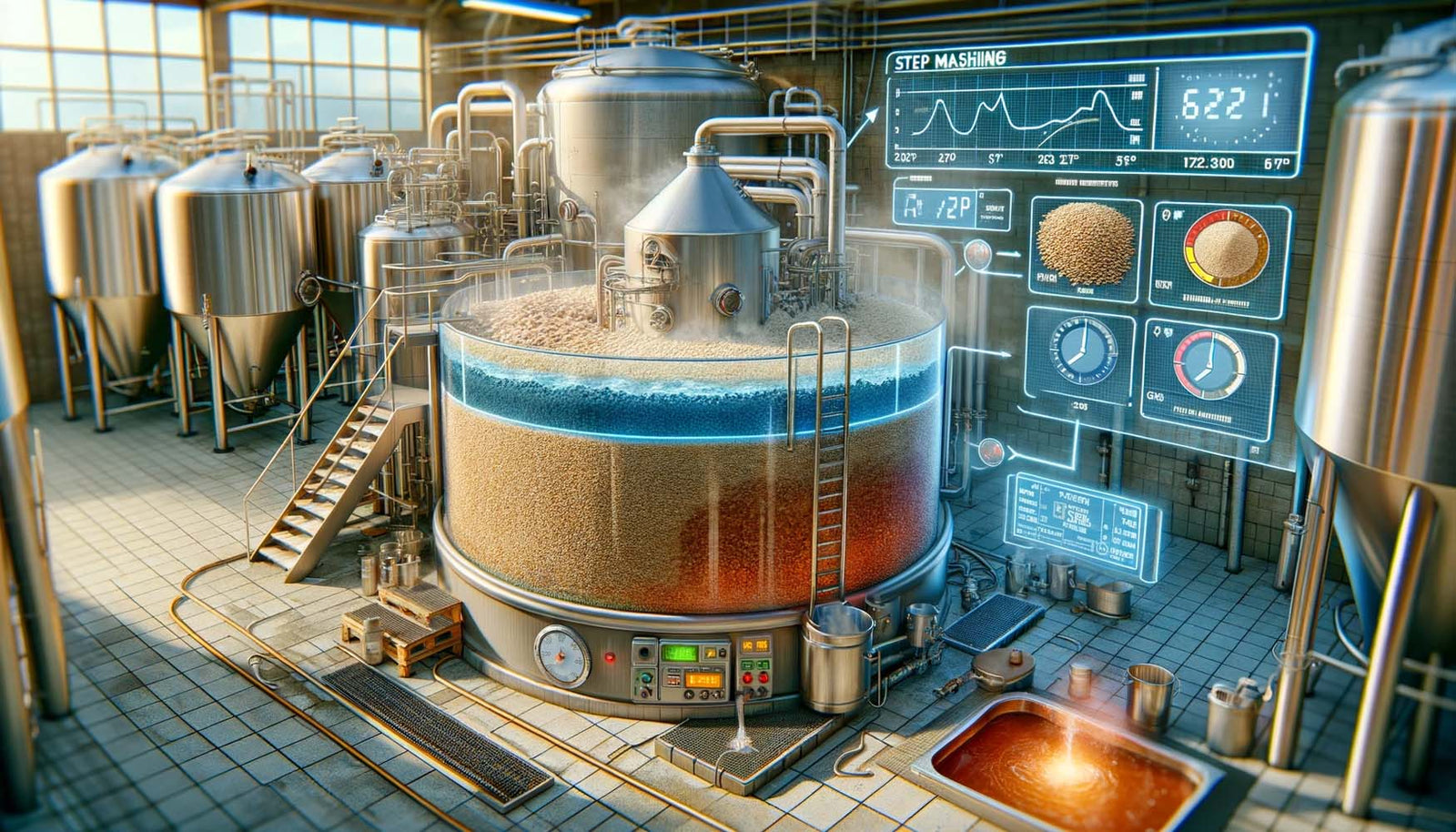

Step Mashing Explained

January 25, 2024 9 min read

Step Mashing Explained

Step mashing is a fundamental technique used in the brewing process to extract the maximum amount of sugars from the grains. By strategically controlling the temperature during mashing, brewers can activate different enzymes that break down complex carbohydrates into fermentable sugars. This article will explain the basics of step mashing, its importance in brewing, various techniques and methods, the role of enzymatic activity, the effects of different temperatures, step mashing for different beer styles, its advantages over other mashing techniques, and useful tips and tricks for success.

The Basics of Step Mashing

Step mashing involves a series of temperature rests during the mashing process, with each rest designed to activate specific enzymes and achieve desired results. The mash consists of malted grains mixed with hot water to convert the starches in the grain to sugars. Step mashing typically consists of two to four temperature rests, although more complex mashing regimes can involve even more steps.

During each temperature rest, enzymes present in the malted grains become active and convert starches into sugars. The primary enzymes involved in step mashing are alpha-amylase and beta-amylase. Alpha-amylase works best in the range of 65-70°C (149-158°F) and breaks down starches into long chains of sugars, while beta-amylase is most effective in the range of 62-67°C (144-153°F) and breaks down these long chains into shorter, fermentable sugars.

Let's delve deeper into the fascinating process of step mashing. The first temperature rest, known as the protein rest, typically takes place at around 50-55°C (122-131°F). During this rest, enzymes called proteases become active and break down proteins present in the malted grains. This step helps to improve the clarity and stability of the final beer by reducing the likelihood of haze-causing proteins.

After the protein rest, we move on to the next temperature rest, known as the saccharification rest. This rest usually occurs at around 63-68°C (145-154°F) and is where the magic of converting starches into sugars truly happens. The alpha-amylase enzyme starts working its wonders, breaking down the long chains of starches into complex sugars. These complex sugars will later be fermented by yeast to produce alcohol and carbon dioxide.

As we progress through the step mashing process, we reach the next temperature rest called the mash-out. This rest typically occurs at around 75-78°C (167-172°F) and serves to halt enzymatic activity. By raising the temperature, we effectively denature the enzymes, ensuring that no further conversion of starches into sugars occurs. This step helps to preserve the desired sugar profile and prevents over-fermentation.

For brewers seeking to achieve specific characteristics in their beer, additional temperature rests can be incorporated into the step mashing process. These rests can target specific enzymes and promote the creation of particular sugars, leading to unique flavors and mouthfeel in the final product. Some brewers may choose to include a rest at around 45-50°C (113-122°F) to activate enzymes that produce more unfermentable sugars, resulting in a sweeter beer.

Step mashing is a technique that allows brewers to have more control over the mashing process and ultimately influence the flavor, body, and overall quality of their beer. By carefully selecting the temperature rests and understanding the role of different enzymes, brewers can create a wide range of beer styles with distinct characteristics.

Why Step Mashing is Important in Brewing

Step mashing offers brewers greater control over the mashing process, allowing them to tailor the characteristics of the final beer. By utilizing different temperature rests, brewers can manipulate the enzyme activity and influence the fermentability, body, and flavor development of the beer.

Step mashing is particularly important for beers that require a significant amount of complex sugars, such as traditional Belgian ales or lagers. These sugars provide richness, complexity, and contribute to the overall mouthfeel and flavor of the beer. Without step mashing, these sugars would not be fully utilized, resulting in a less desirable final product.

One of the key benefits of step mashing is the ability to activate different enzymes at specific temperatures. Enzymes play a crucial role in breaking down complex carbohydrates into simpler sugars that yeast can ferment. By carefully controlling the temperature during each step, brewers can ensure that the enzymes responsible for specific sugar conversions are activated and working optimally.

During the first step of the mash, known as the protein rest, the temperature is typically kept around 122°F (50°C). This temperature range encourages the activity of protease enzymes, which break down proteins into smaller peptides. This step helps to improve the clarity and stability of the final beer, as excessive protein content can lead to haze and instability.

Following the protein rest, the temperature is raised to around 149°F (65°C) for the saccharification rest. This is where the magic happens. The enzymes responsible for converting complex starches into fermentable sugars, such as amylase and beta-glucanase, are most active in this temperature range. By holding the mash at this temperature for a specific duration, brewers can ensure that these enzymes have sufficient time to break down the starches and create a more fermentable wort.

After the saccharification rest, some brewers choose to perform a mash-out step, where the temperature is raised to around 168°F (76°C). This helps to denature the enzymes and halt any further enzymatic activity, ensuring that the sugar conversion is complete and preventing any further degradation of the wort.

Step mashing is particularly beneficial for beers that require a high degree of fermentability, such as dry and crisp lagers. By carefully selecting the temperature rests and durations, brewers can encourage the production of highly fermentable sugars, resulting in a beer with a lower final gravity and a drier finish.

On the other hand, step mashing can also be used to promote the production of more complex sugars, which contribute to the body, mouthfeel, and overall flavor of the beer. For example, in the production of traditional Belgian ales, brewers may incorporate a step called the beta-glucan rest, where the temperature is held around 122°F (50°C) for an extended period. This encourages the production of long-chain sugars, known as beta-glucans, which contribute to the characteristic fullness and viscosity of these beers.

Overall, step mashing provides brewers with a powerful tool to fine-tune the characteristics of their beers. By manipulating the temperature and duration of each step, brewers can create a wide range of flavors, body profiles, and fermentability levels. Whether aiming for a dry and crisp lager or a rich and complex Belgian ale, step mashing is a technique that allows brewers to unlock the full potential of their ingredients and create truly unique and delicious beers.

Step Mashing Techniques and Methods

There are numerous techniques and methods to perform step mashing, each with its own benefits and considerations. Some common step mashing techniques include multi-step infusion, decoction mashing, and single temperature infusion with temperature adjustments.

In multi-step infusion, the temperature is adjusted by adding hot water or boiling water to raise the temperature. This method allows for greater control, but it may require additional equipment and monitoring. Decoction mashing involves removing a portion of the mash, boiling it, and then returning it to the mash tun to increase the temperature. This technique is traditional and adds complexity and flavor to certain beer styles, but it is time-consuming and requires careful attention to prevent scorching.

Single temperature infusion with temperature adjustments is the simplest and most common method of step mashing. The brewer starts with hot water at a specific temperature and adjusts the temperature over time by adding hot or cold water to maintain the desired rest temperature. This method is convenient and accessible to most brewers, making it a popular choice.

Understanding Enzymatic Activity in Step Mashing

The key to successful step mashing lies in understanding the enzymatic activity at different temperatures. Each temperature rest activates specific enzymes, and by manipulating these temperatures, brewers can control the types and amounts of sugars produced.

The higher temperature rests, typically above 65°C (149°F), favor alpha-amylase activity, resulting in the production of longer, less fermentable sugars. This contributes to body and mouthfeel in the finished beer. Lower temperature rests, between 62-65°C (144-149°F), promote beta-amylase activity, leading to the creation of shorter, more fermentable sugars that will be consumed by yeast during fermentation.

By adjusting the time spent at each temperature rest, brewers can fine-tune the balance between fermentable and unfermentable sugars, influencing factors such as sweetness, dryness, and alcohol content of the beer.

Step Mashing Temperatures and Their Effects

The choice of temperature rests during step mashing plays a significant role in determining the characteristics of the final beer. Different beer styles benefit from specific temperature ranges to achieve desired flavor profiles and characteristics.

For example, lagers typically undergo a protein rest around 50-55°C (122-131°F) to break down proteins and improve clarity. This is followed by a saccharification rest around 65-70°C (149-158°F) to convert starches into fermentable sugars.

On the other hand, certain Belgian ales may incorporate a higher temperature rest around 72-75°C (162-167°F) to encourage the production of more complex sugars, contributing to the beer's full-bodied and sweet characteristics.

Step Mashing for Different Beer Styles

Step mashing allows brewers to tailor the mashing process to suit different beer styles. Different styles require specific sugar profiles, mouthfeel, and fermentation characteristics. By employing step mashing techniques, brewers can create the ideal conditions for a particular style.

For malty beers such as bocks or doppelbocks, step mashing can help promote the production of complex sugars, resulting in a richer and sweeter beer. On the other hand, for more attenuated styles like dry stouts, step mashing can favor the formation of highly fermentable sugars, resulting in a drier and lighter-bodied beer.

Step Mashing vs. Other Mashing Techniques

Compared to other mashing techniques, step mashing offers several advantages. First, it provides increased control over the mashing process, allowing brewers to fine-tune the balance of fermentable and unfermentable sugars. This control translates into greater control over the flavor, body, and mouthfeel of the beer.

Second, step mashing enables the brewer to extract a higher percentage of fermentable sugars from the grain, resulting in higher alcohol content and improved fermentability. This can be particularly important in achieving desired characteristics in higher gravity or sweeter beer styles.

Lastly, step mashing can enhance the overall complexity and depth of flavor in the final beer. By utilizing different temperature rests, brewers can encourage the formation of diverse sugars and compounds that contribute to the unique taste profiles of different beer styles.

Step Mashing for Improved Fermentability and Flavor Development

Step mashing plays a vital role in promoting better fermentability and flavor development in beer. By controlling the temperature during mashing, brewers can optimize the activity of enzymes, resulting in the production of a wide array of sugars suitable for yeast fermentation.

Yeast can more readily consume the sugars produced during step mashing, leading to improved fermentation efficiency and attenuated beer. Moreover, the variety of sugars generated through step mashing adds complexity and depth to the beer's flavor profile, enhancing its overall drinkability.

Step Mashing: Tips and Tricks for Success

When incorporating step mashing into your brewing process, there are several tips and tricks that can help ensure success. Firstly, accurate temperature control is crucial. Use a reliable thermometer and monitor the temperature closely during each rest. Small deviations can significantly impact the outcome.

Secondly, consider the specific requirements of the beer style you are brewing. Research the recommended temperature rests and durations commonly used in that style. This will help you achieve the desired characteristics and ensure your beer stays true to the intended style.

Furthermore, experimenting with different step mashing techniques can yield unique results. Try different temperature combinations, rest durations, and even incorporate decoction mashing for certain styles. Not only will this expand your brewing knowledge, but it can also unlock new flavors and aromas in your beers.

In conclusion, step mashing is an essential technique in brewing that allows brewers to harness the full potential of malted grains. By controlling the temperature and enzyme activity, step mashing enables brewers to produce a wide range of sugars with different fermentability and flavor characteristics. This technique provides greater control, flexibility, and creativity in brewing, resulting in unique and flavorful beers that cater to specific beer styles. Incorporate step mashing into your brewing process and unlock the endless possibilities it offers for crafting exceptional beers.

Ready to take your step mashing to the next level? Bräu Supply is here to elevate your brewing experience with our innovative all-in-one systems. Whether you're a homebrew enthusiast or a microbrew maestro, our Unibräu and Unibräu Pro systems offer unparalleled quality and convenience, allowing you to perfect your craft with precision and ease. With our HERMS system, you'll achieve efficiency and control like never before. And don't forget our robust Unitank fermenters and versatile brew kettles, designed with the discerning brewer in mind. All our products are crafted from the finest 304 stainless steel and boast a modular design powered by electricity, ensuring you get the best value and quality. Plus, with the most available accessories in the business, you can tailor your brewing setup to your exact needs. Check out our products today and discover how Bräu Supply can transform your brewing process!

MORE ARTICLES HOW TO BREW BEER

The ultimate guide to Kveik yeast: Unleashing it's fermentation potential

Revolutionizing home brewing: The simplified art of no sparge brewing

Exploring amber ales: A guide with a twist on the traditional recipe

Mastering cold crashing: Enhancing beer clarity and accelerating the aging process

What is the basic function of the fermenter?

What causes a fermenter to heat up?

The art of lagering: A guide to perfecting the cold conditioning process

Troubleshooting fermentation problems in brewing: A comprehensive guide

Subscribe

Sign up to get the latest on sales, new releases and more …